Introduction:

Laser shearing machines represent a significant technological advancement in the realm of material cutting, offering unparalleled precision, speed, and efficiency. This article explores the intricacies of laser shearing technology, its advantages, and the impact it has on the manufacturing and fabrication industries.

1. **Understanding Laser Shearing Machines**

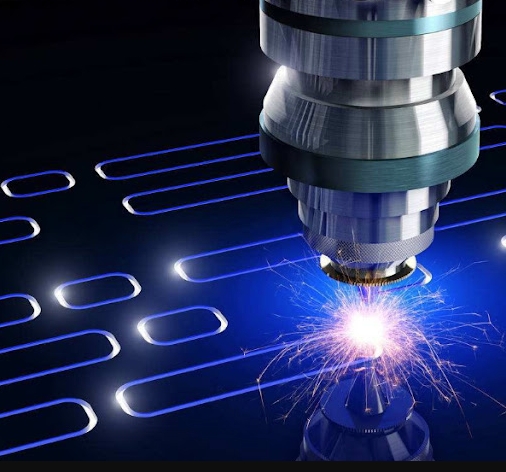

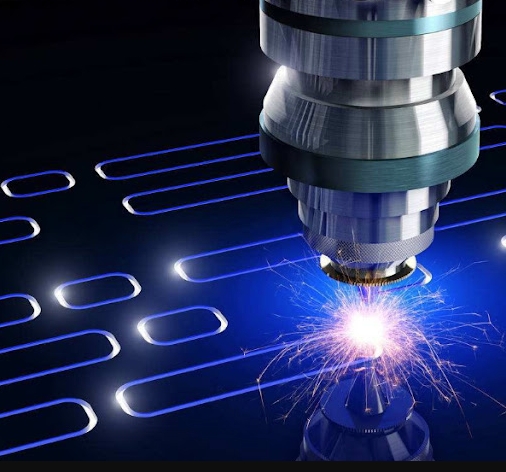

Laser shearing machines use high-powered lasers to cut materials with exceptional accuracy and speed. Unlike traditional mechanical shearing, laser shearing employs a focused beam of light to melt, burn, or vaporize the material, resulting in clean and precise cuts without direct contact or mechanical wear.

2. **Key Features of Laser Shearing Machines**

- **High Precision and Accuracy**: Lasers can achieve extremely accurate cuts with fine detail, suitable for intricate designs and tight tolerances.

- **Versatility**: Capable of cutting a wide range of materials, including metals, plastics, composites, and textiles.

- **Speed and Efficiency**: Laser cutting is much faster than conventional mechanical methods, significantly reducing processing times.

- **Clean and Controlled Cutting**: Produces minimal waste and reduces the need for post-processing, as the laser cauterizes the edges, preventing material fraying.

3. **Advantages of Laser Shearing Technology**

- **Non-contact Process**: Reduces the risk of material contamination or deformation, ensuring higher quality finishes.

- **Reduced Setup Time**: As a programmable, automated process, laser shearing eliminates the need for extensive setup, making it ideal for short production runs and custom projects.

- **Low Maintenance Costs**: With fewer moving parts than mechanical shearing machines, laser systems often have lower maintenance requirements.

- **Energy Efficiency**: Modern laser shearing machines are designed to optimize energy use, reducing operational costs and environmental impact.

4. **Applications in Various Industries**

Laser shearing machines are utilized across diverse sectors, including automotive, aerospace, electronics, and metal fabrication. They are particularly valuable in producing complex components, decorative items, and prototypes where precision and detail are paramount.

5. **Choosing the Right Laser

Shearing Machine**

Selecting the appropriate machine involves considering factors such as the types of materials to be cut, the thickness and size of the sheets, and the desired cutting speed and precision. Additionally, compatibility with existing CAD/CAM systems and the potential for future upgrades should be assessed.

Conclusion:

Laser shearing machines have fundamentally changed the landscape of material cutting, offering a combination of precision, versatility, and efficiency that traditional methods cannot match. As technology continues to evolve, these machines will undoubtedly play a pivotal role in advancing manufacturing and fabrication processes, driving innovation and productivity in various industries.